Designing intelligent systems for sustainable, self-optimizing manufacturing.

At Figure Ground Innovations, we design automated and adaptive systems that form the foundation of smart and autonomous manufacturing environments. Our technology integrates real-time sensing, predictive analytics, and distributed control intelligence to create production systems that can monitor, learn, and self-adjust—minimizing downtime, reducing waste, and maximizing efficiency.

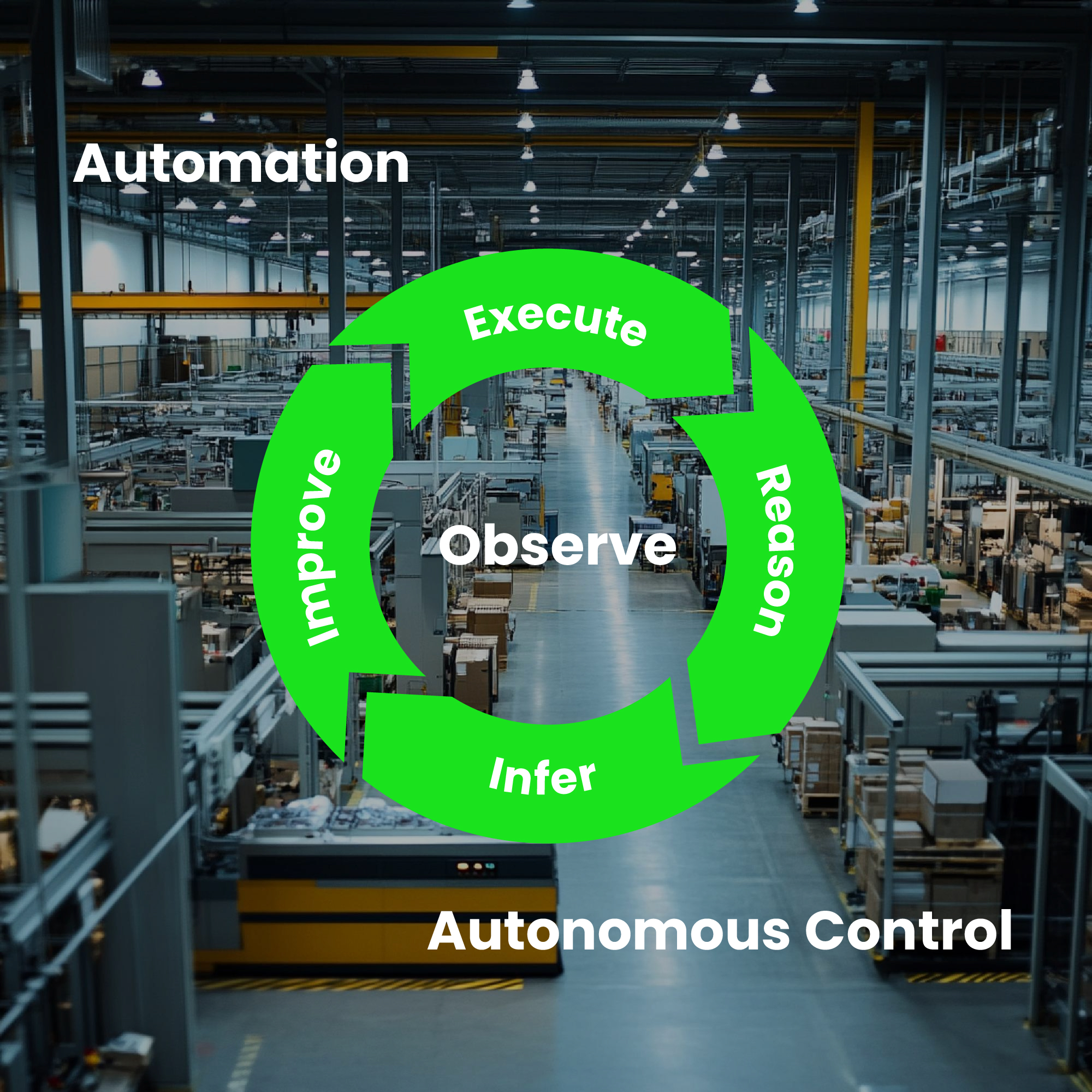

The closed-loop manufacturing paradigm

Our vision is to build a system that not only executes tasks, but also reasons about performance, input variation, improves over time and scales across diverse manufacturing applications from pilot plants to industrial facilities.

Innovative Design & Test Center

Central to our operations is our state-of-the-art Design and Test Center, a facility dedicated to evaluating advanced control systems, sensor networks and process automation architectures before commercial deployment. Within this space, we prototype, integrate, and stress-test everything from smart actuators and modular reactor systems to AI-driven control algorithms. The Center serves as the bridge between laboratory innovation and industrial implementation — allowing us to simulate diverse manufacturing environments, benchmark performance, and continuously refine our adaptive automation platform. Every insight generated here directly informs the design of smarter, safer and efficient production systems across our global portfolio.

Focus Sector

Our current focus is to apply our intelligent process frameworks to the development of a next-generation biorefinery, where automation, adaptive control, and data-driven optimization enable sustainable conversion of biomass into fuels, chemicals, and materials.

- Optimal Feedstock Mix: Identifying the ideal combination of agricultural residues available in a given area to maximize efficiency and output.

- Co-Processing Optimization: Enhancing the processing methods for the selected feedstock mix to ensure seamless integration and superior product quality.

- Product Portfolio Development: Determining the most suitable primary and secondary products for each location, based on available feedstocks and market demand.

Adaptive, data-driven and autonomous production environments.

Observation and Data Synchronization

Every physical process is mirrored by a digital twin: a dynamic, high-fidelity model that continuously ingests live data from sensors, actuators, and control systems.

The twin doesn’t just replicate process parameters; it captures multi-layered signals in real time. Advanced data interfaces ensure continuous synchronization between the digital and physical domains, creating a shared operational context where every fluctuation in the plant is instantly reflected in the simulation.

Pattern Recognition, Reasoning and Inference

Once synchronized, the digital twin begins to interpret process behavior. Using machine-learning algorithms, it analyzes patterns that link process variables to outcomes. Anomalies are not treated as errors but as learning opportunities. The twin identifies correlations invisible to conventional control logic and infers probable causes. These inferences generate predictive insights, allowing the system to anticipate deviations before they manifest in the physical process.

Self-Learning and Model Evolution

The twin then enters a continuous self-learning cycle. Through reinforcement and historical data comparison, it refines its internal models, improving prediction accuracy with each production run. Feedback from process outcomes — both successful and suboptimal — becomes training data. Over time, the digital twin evolves from a passive observer to an adaptive decision-maker, capable of re-parameterizing its own models to align with real-world dynamics, seasonal variability, and changing input conditions such as feedstock composition or demand shifts.

Autonomous Adjustment and Co-Control

Armed with predictive intelligence, the digital twin begins to participate actively in plant control. Within pre-defined safety envelopes, it communicates with the distributed control system to adjust process setpoints, coordinate subsystems, or initiate preventive interventions. These actions form an autonomous feedback loop: observe → infer → learn → act resulting in an environment that continuously self-optimizes — minimizing waste, stabilizing output quality, and conserving energy — all while maintaining transparency for human operators.